Plastic Tooling Making

Brand Name:Hamsan Tooling

Mold Base:LKM;HASCO;DME,etc

Mold Material:2316

Tolerance:+/-0.05mm

Shaping Mode:Plastic Injection Mold

Design Software:AutoCAD;NX;ProE

Packaging Details:Wooden cases

Delivery Time:30 days

Products Details

Products Details

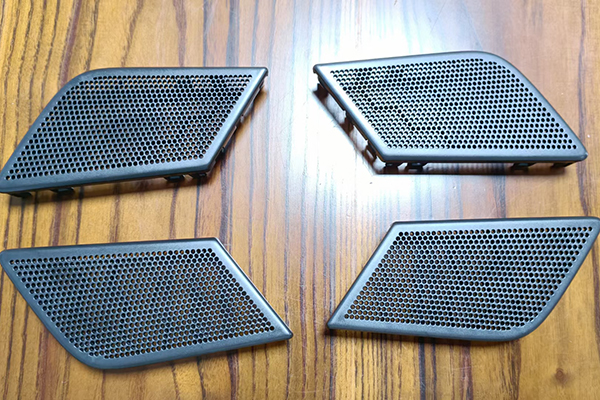

According to the requirements of your customized plastic parts, we design, analyze, improve the structure of the parts, provide you with valuable feedback according to the problems of the parts, and make the customized molds last longer. We have rich experience in automotive interior parts, helping customers solve many complex problems.Product Description:

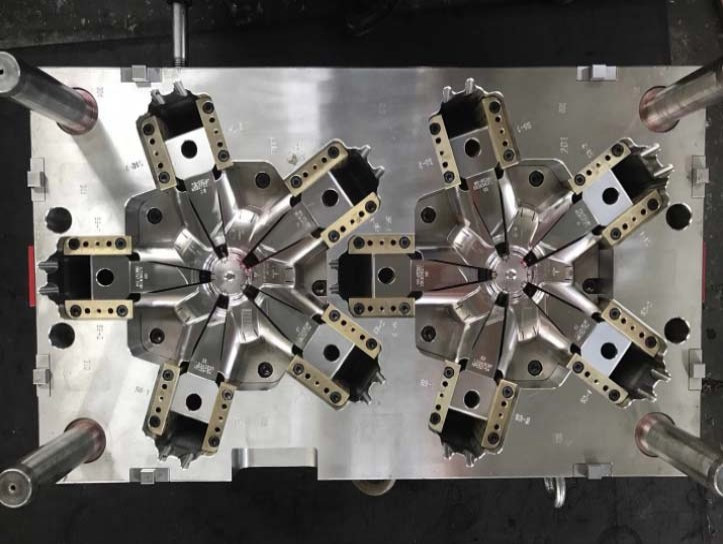

Product name: Multi cavity hot runner injection mould supplier

Mould Material: P20,P20H,718,718H,738,738H,2316,M300,S136,S136H,NAK80,CR12,CR12MOV,SKD11,

DF-2,SKS3,D2,SLD,DC53,H13,SKD61,2344,8407,HD,8418,FDAC,M2,SKH-9,SKH-51,M35

Main Technology: Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc.

Base material: P20, 2738, 2344, 718, S136, 8407, NAK80, SKD61, H13

Product Material: ABS, PP, PC, PA6, PA66, TPU, POM, PBT, PVC,HIPS, PMMA, TPE, PC/ABS, TPV,

Main Technology: Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc.

Equipment: CNC, EDM, Cutting off Machine, plastic machinery, plastic part, etc

Mould Cavity: One cavity, multi-cavity or the same different products be made together

Runner System: Hot runner and cold runner

Finish: Pitting the word, mirror finish, matte surface, striae

Mold Life: 300-500K shots

Mould Precision: +/-0.05mm--+/-0.1mm